Dual Frequencies Integrated Series Single Tank Ultrasonic Cleaner

Product details

Applicable Range:

When choosing a dual-frequency single tank ultrasonic cleaner, different frequency combinations address various cleaning needs and challenges. Below is a guide for each type of dual-frequency ultrasonic cleaning machine (28/40 kHz, 40/80 kHz, 40/120 kHz):

- 28/40 kHz Dual-Frequency Single Tank Ultrasonic Cleaner

- Suitable For:

- Heavy Industry: Such as automotive, machinery manufacturing, steel, etc., which often require handling large particles of dirt and deposits.

- Large Parts Cleaning: For industrial machine parts, large equipment, etc., where parts typically have heavy dirt and deposits.

- Cleaning Challenges Addressed:

- Large Particles of Dirt: Low frequency (28 kHz) generates larger bubbles, effective in removing heavy dirt and deposits.

- Slow Cleaning Speed: 28 kHz provides powerful bubble impact, aiding in rapid removal of large particles of dirt, reducing cleaning time.

- Difficult-to-Remove Deposits: Capable of handling heavy, strongly adhered dirt.

- Suitable For:

- 40/80 kHz Dual-Frequency Single Tank Ultrasonic Cleaner

- Suitable For:

- Electronics and Precision Instruments: Such as electronic components, semiconductors, optical instruments, where high cleaning precision is required.

- Medical Equipment: Such as surgical instruments, medical tools, which need efficient and precise cleaning.

- Cleaning Challenges Addressed:

- Varied Dirt Types: Medium frequency (40 kHz) is suitable for medium-sized dirt particles, while high frequency (80 kHz) handles fine dirt, suitable for complex cleaning needs.

- Precision Parts Cleaning: 80 kHz provides finer cleaning, suitable for parts in electronics and precision instruments that require high cleaning accuracy.

- Uniform Cleaning Issues: The combination of two frequencies can achieve more uniform cleaning results, avoiding uneven cleaning that may occur with a single frequency.

- Suitable For:

- 40/120 kHz Dual-Frequency Single Tank Ultrasonic Cleaner

- Suitable For:

- High Precision Applications: Such as jewelry, optical equipment, medical instruments, requiring extremely high cleaning accuracy and delicacy.

- Complex Structures and Small Parts: For example, precision instruments and high-value items with hard-to-reach areas and extremely fine dirt.

- Cleaning Challenges Addressed:

- Extreme Fine Dirt Cleaning: Low frequency (40 kHz) handles medium-sized dirt, while high frequency (120 kHz) focuses on extremely fine dirt, meeting the needs for cleaning fine dirt.

- Complex Structures Cleaning: 120 kHz can reach into complex structures and tiny crevices, suitable for parts requiring high precision.

- Efficient and Fine Cleaning: Provides a comprehensive cleaning solution, reaching difficult areas for effective and uniform cleaning results.

- Suitable For:

- 28/40 kHz: Suitable for heavy industry and large parts, handling large particles of dirt and deposits, improving cleaning speed.

- 40/80 kHz: Suitable for electronic components, precision instruments, and medical equipment, offering uniform cleaning of medium-sized and fine dirt.

- 40/120 kHz: Suitable for high-precision needs and complex structures, providing cleaning of extremely fine dirt, meeting high precision cleaning requirements.

Choosing the right dual-frequency singel tank ultrasonic cleaning machine can help customers effectively address cleaning process challenges, enhancing cleaning efficiency and quality.

Features:

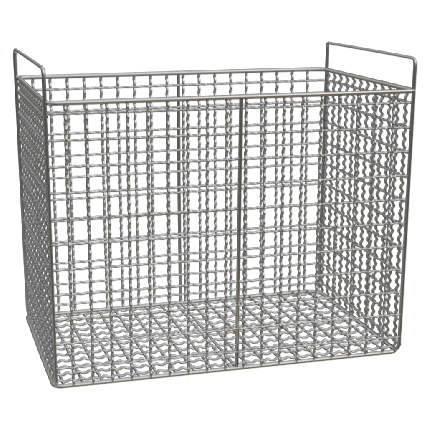

- Fully Imported Stainless Steel Structure: Inner tank with thickened stainless steel plate, resistant to acid and alkali, durable and aesthetically pleasing.

- High "Q" Value Transducers: Utilizing German bonding technology for strong ultrasonic output power. Three dual-frequency options available.

- Solvent Heating and Automatic Temperature Control Device: Temperature control range from room temperature to 99°C.

| Specification | L2-10600 | L2-10900 | L2-11200 | L2-11500 |

|---|---|---|---|---|

| Internal Tank Size (mm) | 400x300x330 | 450x350x380 | 500x400x400 | 550x450x420 |

| External Tank Size (mm) | 500x500x800 | 550x550x800 | 600x600x800 | 650x650x800 |

| Ultrasonic Power | 600W | 900W | 1200W | 1500W |

| Ultrasonic Frequencies | 28/40 40/80 40/120kHz |

28/40 40/80 40/120kHz |

28/40 40/80 40/120kHz |

28/40 40/80 40/120kHz |

| Internal Tank Volume | 40L | 60L | 76L | 99L |

Advantages of Dual-Frequency Single Tank Ultrasonic Cleaners

Compared to single-frequency ultrasonic cleaners, dual-frequency ultrasonic cleaners offer several notable advantages:

- Enhanced Cleaning Performance: Dual-frequency single tank ultrasonic cleaners operate at two distinct frequencies—typically low and high. Low frequencies (e.g., 25-40 kHz) produce larger bubbles, which are effective for removing larger particles of dirt and deposits. High frequencies (e.g., 60-80 kHz) generate smaller bubbles, ideal for cleaning fine dirt and hard-to-reach areas. This dual-frequency capability ensures a more comprehensive and thorough cleaning process.

- Increased Cleaning Efficiency: By handling various types of contaminants simultaneously, dual-frequency single tank ultrasonic cleaners can complete cleaning tasks more quickly. This results in time savings and improved operational efficiency.

- Reduced Risk of Damage: Dual-frequency single tank ultrasonic cleaning machine allow for frequency adjustments based on the cleaning requirements, which helps minimize potential damage to delicate components. High-frequency ultrasound is effective for cleaning small cracks and crevices, while low-frequency ultrasound can address larger surface contaminants.

- Broad Applicability: Dual-frequency single tank ultrasonic cleaners are versatile and can be used across a wide range of cleaning applications, including electronic components, medical devices, jewelry, and industrial parts. This flexibility enhances their utility in various industries.

- Improved Cleaning Uniformity: The ability to operate at different frequencies ensures a more even distribution of ultrasonic energy, reducing the likelihood of uneven cleaning that can occur with single-frequency models.

- Lower Operating Costs: While the initial investment may be higher, the efficiency gains provided by dual-frequency single tank ultrasonic cleaning machine can lead to long-term savings on cleaning agents and labor costs.

In summary, dual-frequency single tank ultrasonic cleaning machine offer a comprehensive and efficient cleaning solution, making them ideal for handling complex cleaning tasks across diverse applications.